language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

Understanding the Factors Influencing Quaternary Diaphragm Pump Pricing

Jun 17,2025

Quaternary diaphragm pumps are specialized devices widely used in various industrial applications, including chemical processing, water treatment, and pharmaceuticals. These pumps are renowned for their ability to handle corrosive and abrasive fluids, which makes them essential in industries where reliability and durability are paramount. However, the price of these pumps can vary significantly based on a range of factors.

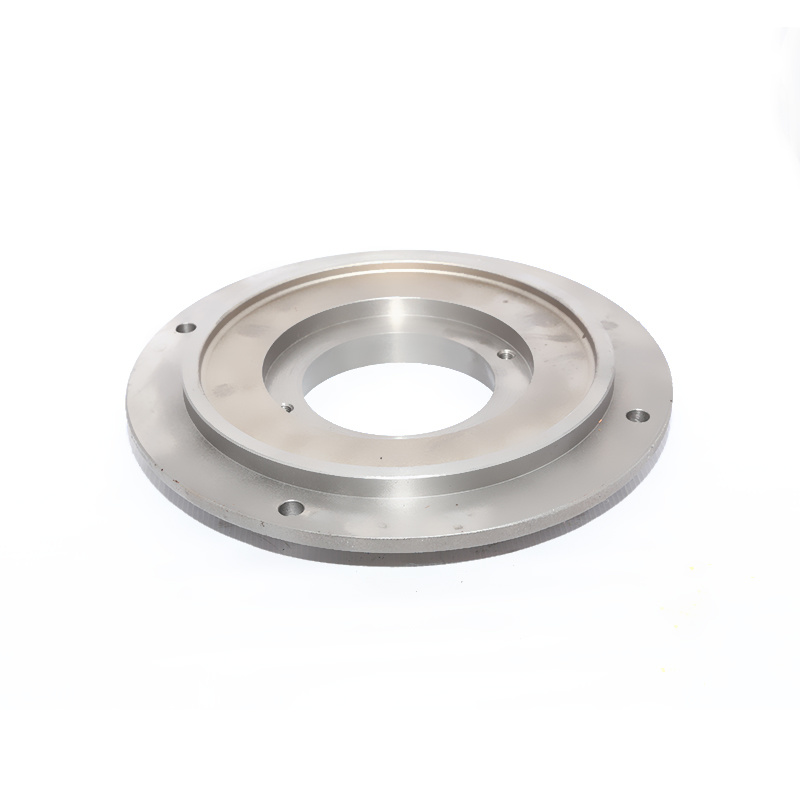

One primary influence on the price of quaternary diaphragm pumps is the material composition. Pumps constructed from high-grade materials such as stainless steel or specialized plastics tend to be more expensive. These materials are chosen for their resistance to chemical corrosion and wear, which can result in lower maintenance costs and longer service life. Therefore, while the initial investment may be higher, the long-term savings can justify the cost.

Another significant factor is the complexity of the pump design. Quaternary diaphragm pumps with advanced features such as variable speed control, integrated monitoring systems, and enhanced sealing mechanisms tend to command higher prices. These features not only improve pump efficiency and performance but also reduce the risk of operational failures. As industries increasingly prioritize automation and precision, the demand for such advanced diaphragm pumps is expected to rise, potentially affecting pricing trends.

Manufacturing location and production volume can also impact the pricing of quaternary diaphragm pumps. Pumps produced in regions with higher labor costs may reflect that in their pricing. Conversely, large-scale manufacturing can lead to economies of scale, resulting in lower prices for clients. Additionally, fluctuations in raw material costs can affect overall pricing strategies; thus, suppliers may adjust prices in response to market dynamics.

Furthermore, the level of customization required can significantly influence the price of quaternary diaphragm pumps. Many clients seek tailored solutions to meet specific operational requirements. Customization can include modifications in size, material, or performance specifications, which can add to the overall cost. Clients should weigh the benefits of customized solutions against their budgets to ensure they make the most informed decision.

In conclusion, the price of quaternary diaphragm pumps is influenced by material composition, design complexity, manufacturing location, production volume, and the need for customization. By understanding these factors, clients can better navigate their purchasing decisions, ensuring they invest in the right equipment for their needs while remaining mindful of budget constraints. As the industrial landscape evolves, being informed about pricing dynamics will empower clients to make strategic choices that align with their operational goals.

One primary influence on the price of quaternary diaphragm pumps is the material composition. Pumps constructed from high-grade materials such as stainless steel or specialized plastics tend to be more expensive. These materials are chosen for their resistance to chemical corrosion and wear, which can result in lower maintenance costs and longer service life. Therefore, while the initial investment may be higher, the long-term savings can justify the cost.

Another significant factor is the complexity of the pump design. Quaternary diaphragm pumps with advanced features such as variable speed control, integrated monitoring systems, and enhanced sealing mechanisms tend to command higher prices. These features not only improve pump efficiency and performance but also reduce the risk of operational failures. As industries increasingly prioritize automation and precision, the demand for such advanced diaphragm pumps is expected to rise, potentially affecting pricing trends.

Manufacturing location and production volume can also impact the pricing of quaternary diaphragm pumps. Pumps produced in regions with higher labor costs may reflect that in their pricing. Conversely, large-scale manufacturing can lead to economies of scale, resulting in lower prices for clients. Additionally, fluctuations in raw material costs can affect overall pricing strategies; thus, suppliers may adjust prices in response to market dynamics.

Furthermore, the level of customization required can significantly influence the price of quaternary diaphragm pumps. Many clients seek tailored solutions to meet specific operational requirements. Customization can include modifications in size, material, or performance specifications, which can add to the overall cost. Clients should weigh the benefits of customized solutions against their budgets to ensure they make the most informed decision.

In conclusion, the price of quaternary diaphragm pumps is influenced by material composition, design complexity, manufacturing location, production volume, and the need for customization. By understanding these factors, clients can better navigate their purchasing decisions, ensuring they invest in the right equipment for their needs while remaining mindful of budget constraints. As the industrial landscape evolves, being informed about pricing dynamics will empower clients to make strategic choices that align with their operational goals.

Latest News