Agricultural-Machinery Valve Block: Enhancing Efficiency in Modern Farming Equipment

Aug 06,2025

As the global agricultural sector continues to embrace automation and precision technology, the demand for advanced hydraulic systems has surged. At the heart of many modern farming machines lies a crucial component that ensures accurate and efficient hydraulic control: the agricultural-machinery valve block.

An agricultural-machinery valve block is a centralized hydraulic unit that regulates the flow and direction of hydraulic fluid to various actuators within farming equipment. These blocks are integral to the operation of tractors, harvesters, plows, seeders, and other machinery used in large-scale agricultural production. By enabling precise control over hydraulic systems, valve blocks significantly improve operational efficiency, reduce mechanical wear, and support multifunctional capabilities in modern farm equipment.

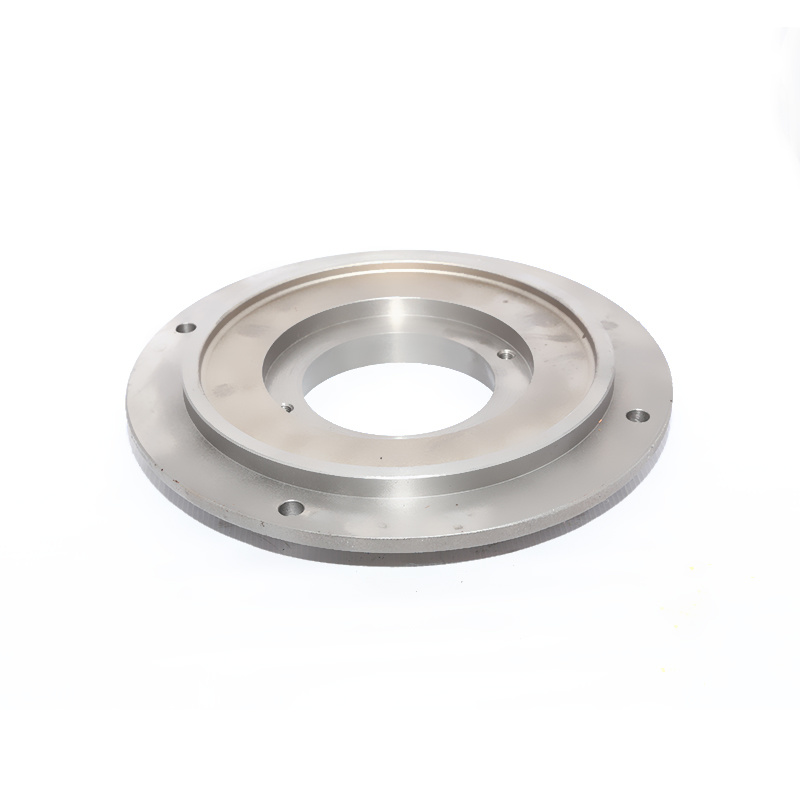

Typically made from high-strength aluminum or steel alloys, valve blocks are designed to withstand extreme pressure and environmental conditions. Their internal configuration includes a network of channels, valves, and ports, allowing for seamless distribution of hydraulic power. Whether lifting, lowering, tilting, or steering, these actions are made possible through the efficient routing of hydraulic fluid controlled by the valve block.

In recent years, the design and functionality of agricultural-machinery valve blocks have evolved significantly. Manufacturers are now integrating modular systems that allow customization for specific machinery models and applications. These modular valve blocks can include features such as proportional control valves, load-sensing technology, and electro-hydraulic actuators. The integration of electronic control units (ECUs) allows farmers to automate processes and monitor system performance in real-time, enhancing productivity and reducing labor costs.

One of the key advantages of using valve blocks in agricultural machinery is the reduction in hydraulic line complexity. Instead of using multiple hoses and fittings to connect separate valves, a single valve block simplifies the system layout, reducing potential leak points and improving maintenance efficiency. This compact design also contributes to space-saving in machine architecture, allowing for more streamlined and lightweight equipment.

The agricultural valve block market is experiencing steady growth, driven by the expanding use of smart farming technologies and the push toward more sustainable agricultural practices. Regions such as North America, Europe, and parts of Asia-Pacific are seeing strong adoption rates, as farmers seek to upgrade their fleets with high-performance, automated solutions. Leading manufacturers in this field include Bosch Rexroth, Bucher Hydraulics, Danfoss, and HydraForce, all of which are investing heavily in R&D to develop more intelligent, durable, and eco-friendly valve block systems.

Sustainability is also becoming a focal point in valve block production. Companies are exploring environmentally conscious materials, improving energy efficiency, and designing systems that reduce fluid waste. These efforts align with the broader goal of minimizing the environmental impact of agricultural operations while maintaining high productivity.

In conclusion, the agricultural-machinery valve block is more than just a hydraulic component; it is a critical enabler of precision, automation, and sustainability in modern farming. As technology continues to evolve, these compact power centers will play an increasingly important role in helping the agricultural industry meet the growing global demand for food while optimizing resources and reducing environmental strain.

Latest News