language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

What Sets Simplex Diaphragm Pump Factories Apart in Quality Control: A Comprehensive Analysis

Jul 08,2025

What Sets Simplex Diaphragm Pump Factories Apart in Quality Control

Table of Contents

- Introduction to Simplex Diaphragm Pumps

- The Importance of Quality Control in Pump Manufacturing

- The Manufacturing Process of Simplex Diaphragm Pumps

- Advanced Technologies Utilized in Quality Control

- Materials Selection and Its Impact on Quality

- Rigorous Testing Procedures: Ensuring Reliability

- Certifications and Industry Standards

- Staff Training and Development: A Key Factor

- Conclusion

- Frequently Asked Questions

Introduction to Simplex Diaphragm Pumps

Simplex diaphragm pumps have become essential in various industries, including chemical processing, water treatment, and food production. Their ability to handle a wide range of liquids safely and efficiently makes them a popular choice among manufacturers and industrial users. Understanding what sets Simplex diaphragm pump factories apart in terms of quality control can provide insights into why these pumps are favored for critical applications.

The Importance of Quality Control in Pump Manufacturing

Quality control is a fundamental aspect of manufacturing that directly impacts the performance, durability, and reliability of products. In the context of Simplex diaphragm pumps, effective quality control ensures that every pump meets strict industry standards and performs as expected under various operating conditions. The following points emphasize the significance of maintaining high-quality standards in pump manufacturing:

1. Reliability

Reliability is paramount for users of diaphragm pumps. A failure can lead to significant operational delays and financial losses. Stringent quality control measures help minimize the risk of defects and ensure that pumps function optimally.

2. Safety

Many diaphragm pumps handle hazardous materials. Quality control processes help ensure that pumps are constructed to prevent leaks and failures, safeguarding both operators and the environment.

3. Customer Satisfaction

High-quality pumps lead to satisfied customers. Consistent performance builds trust, encouraging repeat business and long-term relationships between manufacturers and clients.

The Manufacturing Process of Simplex Diaphragm Pumps

The manufacturing of Simplex diaphragm pumps involves several intricate steps that require precision and expertise. The following outlines the key stages in the production process:

1. Design and Engineering

The process begins with meticulous design and engineering, where factors such as pump capacity, material compatibility, and application-specific requirements are considered. Advanced software tools are often employed to create detailed designs that facilitate efficient manufacturing.

2. Component Fabrication

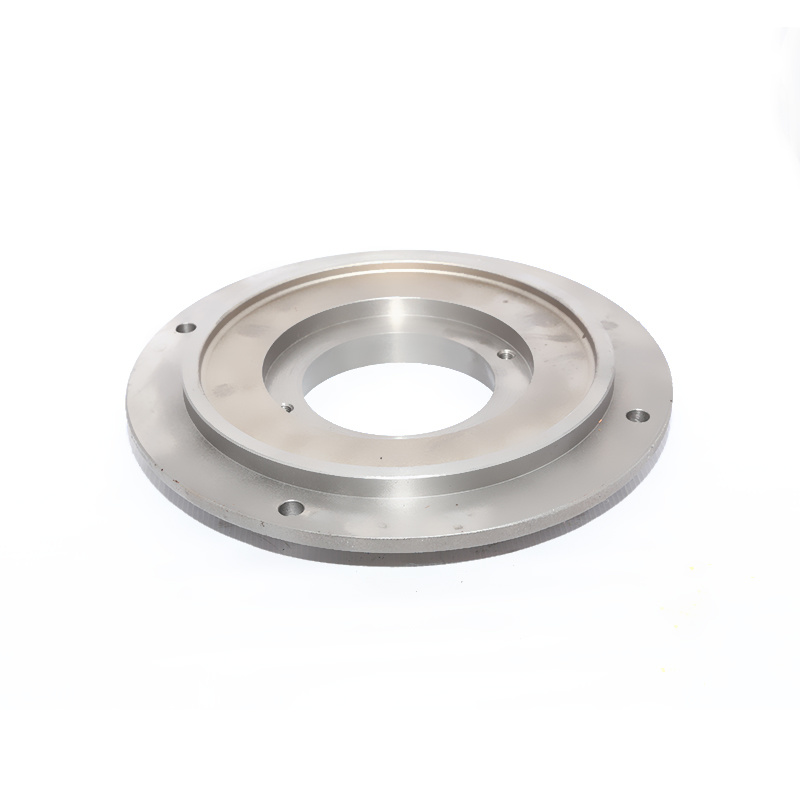

Once the design is finalized, various components of the pump are fabricated. This includes diaphragm plates, housings, and valves, each produced with high-grade materials to ensure durability.

3. Assembly

The assembly process involves skilled technicians who meticulously put together the fabricated components. Attention to detail is crucial during assembly to prevent issues that might arise from improper fitting or alignment.

Advanced Technologies Utilized in Quality Control

Simplex diaphragm pump factories leverage advanced technologies to enhance their quality control measures. These technologies include:

1. Automated Inspection Systems

Automated inspection systems utilize advanced imaging and measurement technologies to assess the quality of components and finished products. These systems can detect minute defects that the human eye may overlook, leading to higher standards of quality.

2. Real-Time Monitoring

Real-time monitoring systems track production processes, allowing for immediate adjustments if deviations from quality standards occur. This proactive approach ensures that potential issues are addressed before they escalate.

3. Data Analytics

Factories employ data analytics to analyze production data comprehensively. Insights gained from this analysis help identify patterns in defects, leading to continuous improvements in manufacturing processes.

Materials Selection and Its Impact on Quality

The selection of materials is critical in the manufacturing of Simplex diaphragm pumps. High-quality materials contribute significantly to the longevity and performance of the pumps. Key considerations include:

1. Corrosion Resistance

Many applications involve corrosive substances. Therefore, choosing materials that resist corrosion ensures the pump's integrity and extends its lifespan.

2. Strength and Durability

Pumps must withstand high pressures and varying temperatures. High-strength materials ensure that pumps operate reliably over prolonged periods, even under challenging conditions.

3. Compatibility

Materials must be compatible with the fluids being pumped. Proper selection prevents issues like chemical reactions that can compromise pump performance.

Rigorous Testing Procedures: Ensuring Reliability

Quality control in Simplex diaphragm pump factories includes comprehensive testing procedures that evaluate the performance and reliability of each pump before it reaches the market. These procedures encompass:

1. Functionality Testing

Pumps undergo functionality tests to ensure they operate as designed. This includes checking flow rates, pressure levels, and overall performance under various conditions.

2. Endurance Testing

Endurance tests simulate prolonged operation to assess how pumps perform over time. These tests help identify potential weaknesses that may not be apparent during standard functionality testing.

3. Leak Testing

Leak testing is crucial, particularly for pumps handling hazardous materials. Factories employ various methods to ensure that pumps are leak-proof, thus safeguarding user safety and environmental integrity.

Certifications and Industry Standards

Adherence to industry standards and obtaining relevant certifications is a hallmark of reputable Simplex diaphragm pump factories. These certifications signify that products meet specific quality and safety requirements. Key certifications include:

1. ISO Certification

ISO certifications indicate that a factory adheres to international quality management standards, ensuring consistent quality in production processes.

2. CE Marking

CE marking demonstrates that pumps meet EU safety, health, and environmental protection requirements, making them compliant for sale within the European Union.

3. API Standards

The American Petroleum Institute (API) sets specific standards for pumps used in the petroleum and natural gas industries. Compliance with API standards signifies that a factory produces pumps that meet rigorous industry expectations.

Staff Training and Development: A Key Factor

The expertise and skill of factory staff are crucial in maintaining high-quality standards. Simplex diaphragm pump factories prioritize staff training and development through:

1. Continuous Education

Ongoing training programs help staff stay updated on the latest technologies and manufacturing techniques, fostering a culture of excellence within the factory.

2. Cross-Training

Cross-training employees in different areas of manufacturing enhances collaboration and ensures that all staff understand the importance of quality control across the production process.

3. Safety Training

Safety training is integral to the production process, particularly when dealing with hazardous materials. Trained staff can identify potential risks and implement safety measures effectively.

Conclusion

In conclusion, what sets Simplex diaphragm pump factories apart in terms of quality control is a combination of advanced manufacturing processes, rigorous testing, stringent material selection, and an unwavering commitment to staff training. These elements work together to produce reliable, high-quality pumps that meet the diverse needs of various industries. As manufacturers continue to innovate and enhance their quality assurance measures, Simplex diaphragm pumps will undoubtedly remain a trusted choice for industrial applications.

Frequently Asked Questions

1. What is a diaphragm pump, and how does it work?

A diaphragm pump uses a flexible diaphragm to create a pumping action. As the diaphragm moves up and down, it creates a vacuum that draws liquid into the pump and then expels it using pressure.

2. What industries commonly use Simplex diaphragm pumps?

Simplex diaphragm pumps are widely used in industries such as chemical processing, water treatment, food and beverage production, and pharmaceuticals.

3. How often should diaphragm pumps be maintained?

Regular maintenance is essential for diaphragm pumps. It's recommended to conduct inspections and service them every six months or as per the manufacturer's guidelines.

4. What are the advantages of using Simplex diaphragm pumps over other types of pumps?

Simplex diaphragm pumps offer advantages such as the ability to handle corrosive liquids, self-priming capabilities, and reduced risk of leaks, making them suitable for sensitive applications.

5. How can I ensure the quality of the diaphragm pump I purchase?

To ensure quality, purchase pumps from reputable manufacturers with established quality control processes, and check for certifications and compliance with industry standards.

Latest News