Gear Pumps in the Automotive Industry: An Essential Component for Performance and Efficiency

Sep 12,2025

Gear Pumps in the Automotive Industry: An Essential Component for Performance and Efficiency

The automotive industry is a complex ecosystem, relying on various components to ensure optimal performance and efficiency. Among these components, **gear pumps** play a crucial role, providing essential functions in fluid transfer and management. In this extensive article, we will delve deep into the significance of gear pumps in automotive applications, examining their design, operation, advantages, and market trends. By the end of this guide, you will understand why gear pumps are not just essential but also a cornerstone of automotive technology.

Table of Contents

- Introduction to Gear Pumps

- Understanding Gear Pump Design

- Types of Gear Pumps Used in Automotive Applications

- Applications of Gear Pumps in the Automotive Industry

- Advantages of Gear Pumps

- Choosing the Right Gear Pump for Automotive Use

- Future Trends in Gear Pumps for the Automotive Sector

- Frequently Asked Questions

- Conclusion

Introduction to Gear Pumps

Gear pumps are positive displacement pumps characterized by their design, which features two or more interlocking gears. These pumps are primarily used to move fluids by trapping a fixed amount of fluid between the gears and then forcing it out through the discharge pipe. In the automotive sector, gear pumps facilitate the circulation of oils and other fluids, playing a pivotal role in maintaining the overall functionality and efficiency of vehicles.

Understanding Gear Pump Design

The design of a gear pump is straightforward yet efficient. Typically, a gear pump consists of two gears that rotate in opposite directions within a closed casing. The rotating motion creates a vacuum that draws fluid into the pump, which is subsequently expelled through the outlet. Here are the critical elements that define the design of gear pumps:

1. Gears

Gear pumps usually employ two types of gears: spur gears and helical gears. **Spur gears** offer simplicity and reliability, making them suitable for various applications. On the other hand, **helical gears** provide smoother operation and quieter performance, which can be beneficial in noise-sensitive environments.

2. Pump Casing

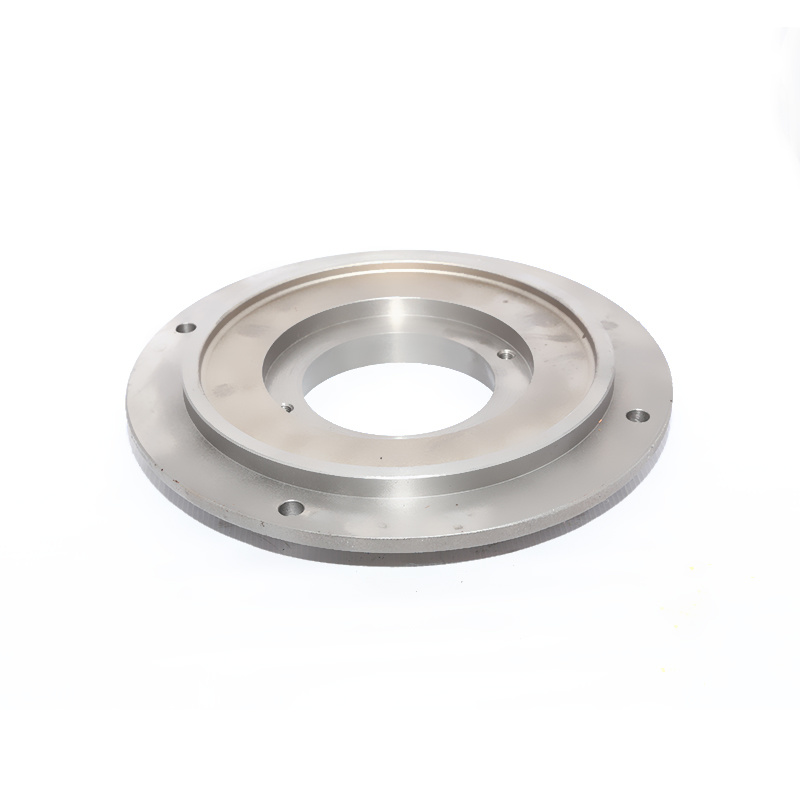

The pump casing is designed to contain the gears and the fluid being pumped. It must withstand high pressures and temperatures while preventing leaks. High-quality materials such as cast iron or aluminum are often used to enhance durability.

3. Seals and Bearings

Seals are critical in preventing fluid leakage, while bearings support the rotation of the gears. These components must be robust to ensure long-lasting performance, especially in high-demand automotive applications.

Types of Gear Pumps Used in Automotive Applications

In the automotive industry, various types of gear pumps are utilized, each catering to specific needs:

1. Internal Gear Pumps

Internal gear pumps feature one gear that is located inside another. This design allows for a smoother flow of fluids and is often employed in hydraulic systems, fuel injection, and lubrication applications.

2. External Gear Pumps

External gear pumps consist of two gears that are positioned outside one another. They are widely used for transferring fuel, lubricants, and other automotive fluids due to their ability to handle a wide range of viscosities.

3. Gear Motors

Gear motors combine the functions of a gear pump and a motor, providing a compact solution for automotive applications. They are primarily used in systems requiring precise fluid control, such as power steering and brake systems.

Applications of Gear Pumps in the Automotive Industry

Gear pumps have a multitude of applications in the automotive industry, making them indispensable for various functions:

1. Lubrication Systems

One of the primary roles of gear pumps in vehicles is to circulate engine oil to lubricate moving parts. This function is crucial in reducing friction, enhancing engine longevity, and improving overall efficiency.

2. Fuel Transfer

Gear pumps are commonly used in fuel systems to transfer gasoline or diesel from the tank to the engine. Their ability to generate high pressure allows for efficient fuel delivery, ensuring optimal engine performance.

3. Hydraulic Systems

In vehicles equipped with hydraulic brakes or steering systems, gear pumps facilitate the movement of hydraulic fluids. This ensures smooth operation and responsiveness in critical vehicle functions.

4. Cooling Systems

Gear pumps are also employed in the cooling systems of automotive engines, ensuring that coolant is circulated effectively to prevent overheating. Maintaining optimal engine temperature is vital for performance and efficiency.

Advantages of Gear Pumps

Gear pumps offer several benefits that make them highly regarded in the automotive sector:

1. High Efficiency

Gear pumps provide a consistent flow rate, ensuring efficient fluid transfer. Their design minimizes energy loss, contributing to better overall vehicle performance.

2. Durability

Constructed from robust materials, gear pumps are designed for longevity. They can withstand high pressures and temperatures, making them suitable for demanding automotive environments.

3. Versatility

These pumps can handle a wide range of fluids, from low-viscosity gasoline to high-viscosity oils, making them versatile for various applications.

4. Low Maintenance

Gear pumps require minimal maintenance due to their simple design and high durability. This aspect can significantly reduce the overall operational costs for automotive manufacturers.

Choosing the Right Gear Pump for Automotive Use

When selecting a gear pump for automotive applications, several factors should be considered:

1. Fluid Characteristics

Understanding the viscosity and chemical properties of the fluid being pumped is crucial. This knowledge will help in selecting a gear pump suited to handle the specific fluid requirements.

2. Flow Rate Requirements

Determining the required flow rate is essential for selecting the right gear pump. The pump must deliver sufficient fluid volume without sacrificing pressure.

3. Pressure Specifications

Different applications may demand varying pressure levels. It is vital to choose a gear pump that can operate effectively within the required pressure range.

4. Size and Mounting Options

The physical size of the gear pump and its mounting configuration should align with the vehicle's design. Compact and lightweight options are often preferred in modern automotive applications.

Future Trends in Gear Pumps for the Automotive Sector

The automotive industry is continuously evolving, and gear pumps are no exception. Here are some future trends that are expected to shape the use of gear pumps:

1. Increased Use of Electric Vehicles (EVs)

As the automotive industry shifts towards electric vehicles, the demand for gear pumps in battery cooling and hydraulic systems will rise. Manufacturers are likely to innovate gear pumps that cater specifically to the unique requirements of EVs.

2. Smart Pump Technology

Integrating smart technology into gear pumps will enhance their functionality. This innovation may include real-time monitoring of pump performance and fluid dynamics, leading to improved efficiency and predictive maintenance.

3. Sustainable Materials

The push for sustainability in manufacturing will lead to the development of gear pumps made from eco-friendly materials, reducing the environmental impact of automotive production.

4. Enhanced Performance Features

Future gear pumps are expected to feature advanced designs that improve performance, reduce noise, and increase energy efficiency, aligning with the automotive industry's focus on performance and sustainability.

Frequently Asked Questions

1. What is a gear pump used for in automobiles?

Gear pumps are primarily used in automobiles for lubrication, fuel transfer, hydraulic systems, and cooling systems.

2. How does a gear pump work?

A gear pump works by trapping a fixed amount of fluid between its interlocking gears and forcing it out through the discharge pipe as the gears rotate.

3. What are the main advantages of using gear pumps?

Some advantages include high efficiency, durability, versatility, and low maintenance requirements.

4. Are gear pumps suitable for viscous fluids?

Yes, gear pumps are excellent for handling a wide range of fluids, including those with high viscosity.

5. How do I choose the right gear pump for my application?

Consider factors like fluid characteristics, flow rate requirements, pressure specifications, and size before selecting a gear pump.

Conclusion

In summary, gear pumps are essential components in the automotive industry, playing a pivotal role in various applications such as lubrication, fuel transfer, and hydraulic systems. Their advantages, including high efficiency and durability, make them indispensable for modern vehicles. As the automotive landscape continues to evolve, the importance of gear pumps will only grow, driven by advancements in technology and the shift towards sustainable practices. Understanding the design, applications, and future trends of gear pumps will equip industry professionals with the knowledge needed to leverage these critical components effectively. Investing in the right gear pump can lead to improved vehicle performance and efficiency, ultimately benefiting manufacturers and consumers alike.

Latest News