language

English

العربية

বাংলাদেশ

Български

Hrvatski

Česky

Dansk

Nederland

Esperanto

Slovenski

filipino

Suomi

Français

Maori

Georgian

Deutsch

Ελλάδα

ישראל

इंडिया

Magyarország

Ísland

Indonesia

Irlanda

Italia

日本語

Sovensko

Հայաստան

한국

Kyrgyz

ປະເທດລາວ

Latvian

Lithuanian

Luxembourgish

Macedonian

Малайская

Maltese

Монгол улс

ဗမာ

नेपाल

Norge

ایران

Polska

Portugal

România

Российская

Србија

Србија

Bosanski

Slovenian

Беларус

España

Sverige

Точик

ประเทศไทย

Türk

Azərbaycan

Uzbek

Việt Nam

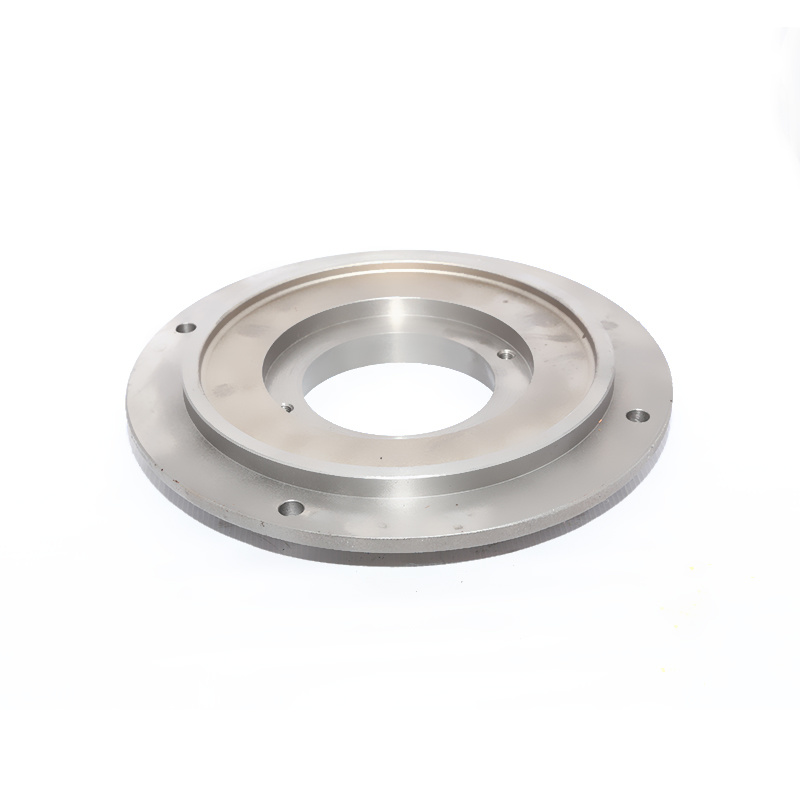

Understanding Gear Pumps: Essential Insights for Industrial Applications

Sep 05,2025

Gear pumps are a critical component in the realm of industrial equipment, particularly within the category of pumps and vacuum devices. These pumps are designed to transfer fluids efficiently by using the meshing of gears, offering a reliable solution for managing various types of liquids, including oils, fuels, and chemicals. Understanding the fundamental principles and applications of gear pumps is essential for professionals seeking to optimize their operations and ensure the longevity of their systems.

The primary function of a gear pump is to move fluid through the rotation of gears. As the gears turn, they create a vacuum that draws fluid into the pump chamber, where it is then forced out through the discharge port. This positive displacement mechanism allows gear pumps to handle a wide range of viscosities, making them suitable for both low and high viscosity fluids. The design of these pumps ensures a consistent flow rate, which is crucial for processes requiring precise fluid management.

One of the notable advantages of gear pumps is their durability and reliability. Constructed from robust materials, they can withstand the rigors of industrial environments, reducing maintenance needs and downtime. Additionally, gear pumps often feature a simple design, which facilitates easy maintenance and repair, making them a practical choice for many applications.

When selecting a gear pump for a specific application, several factors must be considered. First, the viscosity of the fluid being pumped plays a significant role in the pump's performance. Higher viscosity fluids require pumps designed to handle increased resistance. Secondly, the required flow rate and pressure must align with the pump's specifications to ensure optimal operation. It's also essential to factor in the material compatibility, especially when dealing with corrosive fluids.

Another important consideration is the noise level generated by the pump during operation. Gear pumps can produce audible noise, and in sensitive environments, it may be beneficial to explore options that minimize sound. Moreover, understanding the pump's efficiency can help in reducing energy costs, making it a vital aspect for businesses aiming to improve their operational efficiency.

In summary, gear pumps are invaluable in the industrial equipment sector, providing reliable and efficient fluid transfer solutions. By understanding their operational principles, advantages, and selection criteria, professionals can make informed decisions that enhance their systems' performance and longevity. As industries continue to evolve, staying updated on the latest advancements in gear pump technology will be crucial for maintaining a competitive edge.

The primary function of a gear pump is to move fluid through the rotation of gears. As the gears turn, they create a vacuum that draws fluid into the pump chamber, where it is then forced out through the discharge port. This positive displacement mechanism allows gear pumps to handle a wide range of viscosities, making them suitable for both low and high viscosity fluids. The design of these pumps ensures a consistent flow rate, which is crucial for processes requiring precise fluid management.

One of the notable advantages of gear pumps is their durability and reliability. Constructed from robust materials, they can withstand the rigors of industrial environments, reducing maintenance needs and downtime. Additionally, gear pumps often feature a simple design, which facilitates easy maintenance and repair, making them a practical choice for many applications.

When selecting a gear pump for a specific application, several factors must be considered. First, the viscosity of the fluid being pumped plays a significant role in the pump's performance. Higher viscosity fluids require pumps designed to handle increased resistance. Secondly, the required flow rate and pressure must align with the pump's specifications to ensure optimal operation. It's also essential to factor in the material compatibility, especially when dealing with corrosive fluids.

Another important consideration is the noise level generated by the pump during operation. Gear pumps can produce audible noise, and in sensitive environments, it may be beneficial to explore options that minimize sound. Moreover, understanding the pump's efficiency can help in reducing energy costs, making it a vital aspect for businesses aiming to improve their operational efficiency.

In summary, gear pumps are invaluable in the industrial equipment sector, providing reliable and efficient fluid transfer solutions. By understanding their operational principles, advantages, and selection criteria, professionals can make informed decisions that enhance their systems' performance and longevity. As industries continue to evolve, staying updated on the latest advancements in gear pump technology will be crucial for maintaining a competitive edge.

Latest News